- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

News

What is a Die Casting Process?

At its core, die casting involves the injection of molten metal into a precision-crafted mold, or die, under high pressure. This mold is typically made from hardened steel or alloyed tool steel to withstand the intense heat and pressure involved in the process. Once the molten metal is injected, it ......

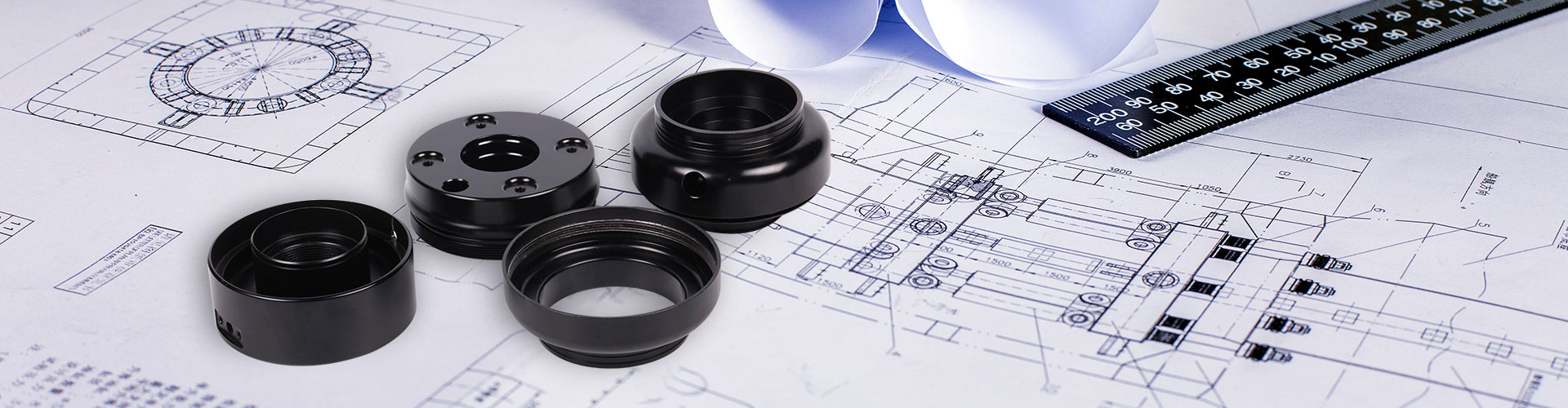

Read MoreWhat are CNC Machining Parts?

CNC machining parts refer to components and elements that are produced through the use of Computer Numerical Control (CNC) machining techniques. CNC machining is a subtractive manufacturing process that employs computer-controlled cutting tools to remove material from a workpiece, leaving behind the......

Read MoreUnderstanding Hydraulic Parts and Their Roles

The world of hydraulics is a fascinating realm where fluids are harnessed to generate incredible power and precision. But behind the scenes, a symphony of carefully engineered components, known as hydraulic parts, work together to make this magic happen.

Read MoreBenefits and Applications of Aluminum Die Casting

The Aluminum Die Casting process starts with the creation of a die, typically made from hardened steel, which defines the shape of the final component. Molten aluminum is then forced into the die cavity at high pressures, filling the mold and forming the part. Once the aluminum cools and solidifies,......

Read MoreWhat Are the Industries That Use Investment Casting?

Investment casting, a versatile and intricate manufacturing process, shines brightest in industries where precision, complexity, and fine details reign supreme. Here, investment casting proves its mettle, offering a potent alternative to die casting when production volumes wouldn't justify the cost......

Read MoreThe Lifeblood of Machines: A Look at Essential Hydraulic Parts

The Lifeblood of Machines: A Look at Essential Hydraulic Parts The world around us is filled with powerful machines that rely on intricate systems to function. From massive construction equipment to delicate robotics, many of these machines utilize a remarkable technology: hydraulics. But what make......

Read More