- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

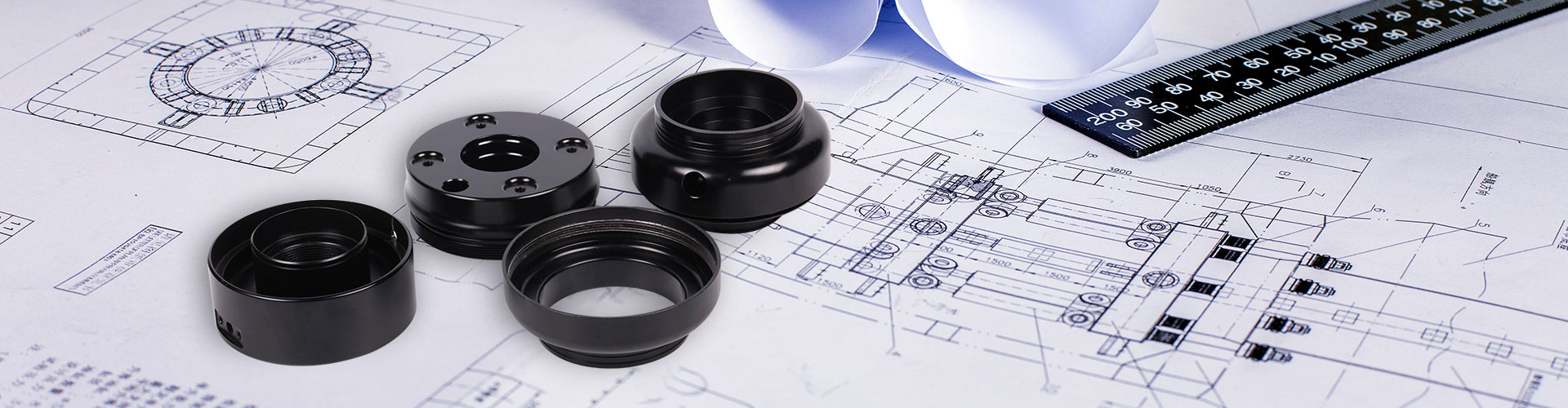

What Are the Industries That Use Investment Casting?

2024-05-13

Investment casting, a versatile and intricate manufacturing process, shines brightest in industries where precision, complexity, and fine details reign supreme. Here, investment casting proves its mettle, offering a potent alternative to die casting when production volumes wouldn't justify the cost.

Taking Flight in Aerospace:

The aerospace industry soars with the aid of investment casting. Here, investment casting crafts high-complexity gas turbine components that are instrumental in gas flow: turbine blades with intricate cooling channels and fuel components with demanding tolerances. These investment cast parts ensure the efficient and reliable operation of aircraft engines, a testament to the precision achievable with investment casting.

Gearing Up for Automotive Applications:

Investment casting doesn't just conquer the skies; it tackles the terrain too. In the automotive realm, investment casting is employed to manufacture components for a diverse range of vehicles. From low-volume, high-performance race cars to heavy-duty workhorses like construction equipment, tractors, and agricultural machinery, investment casting delivers intricate parts that contribute to peak performance and durability.

Saving Lives with Medical Marvels:

The medical sector relies heavily on the precision offered by investment casting. Here, investment casting produces crucial components for MRI machines, the intricate details allowing for clearer and more accurate diagnoses. Wheelchairs, hospital beds, and operating room equipment all benefit from investment cast parts, ensuring smooth operation and patient comfort. Investment cast surgical tools boast exceptional sharpness and intricate features, empowering surgeons with the precision they need to perform delicate procedures.

Beyond the Examples: A Universe of Applications

The impact of investment casting extends far beyond these highlighted industries. Telecommunication equipment, electronics, and even oil and gas exploration rely on investment casting to produce intricate parts that meet demanding performance criteria. Investment casting's ability to handle a wide range of materials, from high-strength alloys to heat-resistant superalloys, further expands its reach across diverse sectors.

The Power of Precision: Why Investment Casting Matters

Investment casting stands out for its ability to produce near-net-shape parts with exceptional dimensional accuracy and intricate details. This translates to several advantages:

Reduced Machining: The high level of detail achieved through investment casting minimizes the need for extensive post-processing machining, saving time and material.

Design Freedom: Investment casting allows for the creation of complex geometries that would be challenging or impossible with other techniques, empowering engineers to push the boundaries of design.

Material Versatility: Investment casting works with a wide range of materials, enabling the creation of parts with specific properties tailored to the application.

Quality and Consistency: Investment casting offers a repeatable and reliable process, ensuring consistent quality across production runs.

In conclusion, investment casting is a cornerstone manufacturing process for industries demanding precision, complexity, and unwavering quality. Its ability to breathe life into intricate designs and handle diverse materials makes it a powerful tool for shaping innovation across a vast spectrum of applications. The next time you witness the marvels of modern technology, from a jetliner soaring through the skies to a life-saving medical device, remember the invisible hand of investment casting, meticulously crafting the intricate components that make it all possible.