- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

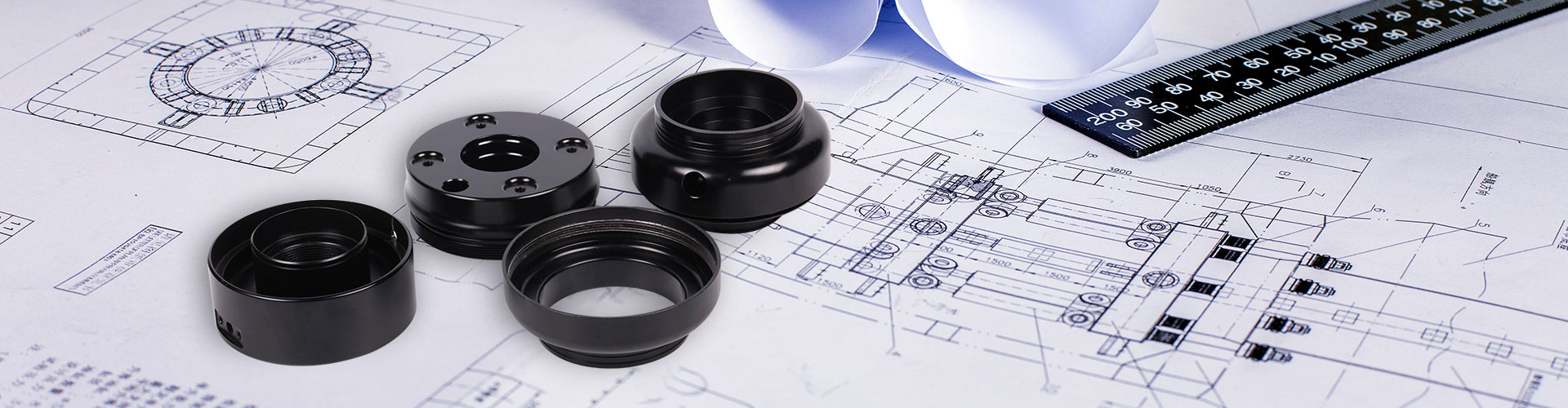

The Lifeblood of Machines: A Look at Essential Hydraulic Parts

2024-04-28

The Lifeblood of Machines: A Look at Essential Hydraulic Parts

The world around us is filled with powerful machines that rely on intricate systems to function. From massive construction equipment to delicate robotics, many of these machines utilize a remarkable technology: hydraulics. But what makes hydraulics work? The answer lies in the essential hydraulic parts that work together seamlessly.

At the heart of any hydraulic system lies the hydraulic fluid. This pressurized liquid transmits power throughout the system, allowing for the control of force and movement. However, to harness the potential of this fluid, a variety of hydraulic parts come into play. Let's explore some of the most crucial ones:

Pumps: These are the workhorses of a hydraulic system. Hydraulic pumps convert mechanical energy, often from an electric motor, into the pressurized fluid that drives the system. Different pump designs exist, each suited for specific pressure and flow requirements.

Motors: Once the hydraulic fluid is pressurized, it can be used to power hydraulic motors. These motors convert the hydraulic energy back into mechanical energy, driving the movement of pistons, gears, or other components.

Cylinders: Hydraulic cylinders are the muscle of the system. These linear actuators use the pressurized fluid to create a telescopic force, pushing or pulling objects with immense power. They are vital components in construction equipment, presses, and lifting machinery.

Valves: Hydraulic valves are the control center of the system. They regulate the flow, pressure, and direction of the hydraulic fluid. Different types of valves exist, such as directional control valves, pressure relief valves, and flow control valves, allowing for precise control over the system's operation.

Filters: To maintain system efficiency and prevent wear, hydraulic filters are essential. They remove contaminants from the hydraulic fluid, ensuring smooth operation and protecting other hydraulic parts from damage.

Accumulators: Hydraulic accumulators act as energy storage devices. They store pressurized fluid, providing a surge of power when needed or smoothing out pressure fluctuations in the system.

Seals and Hoses: Hydraulic systems rely heavily on seals and hoses to prevent leaks and maintain proper pressure. These seemingly simple hydraulic parts play a critical role in system performance and safety.

Beyond the Basics

The world of hydraulic parts extends far beyond these core components. Directional control spools, check valves, pressure gauges, and countless other specialized parts work together to create complex hydraulic systems. The selection and configuration of these hydraulic parts depend on the specific application, ensuring the system delivers the optimal force, speed, and control required.

Ensuring Peak Performance

Maintaining a hydraulic system requires regular inspection, service, and replacement of worn hydraulic parts. Using high-quality hydraulic parts and following proper maintenance procedures are crucial for ensuring the system's longevity, efficiency, and safety.

By understanding the essential hydraulic parts and their functions, we gain a deeper appreciation for the remarkable technology that powers a vast array of machines in our world. From the towering cranes shaping our skylines to the delicate surgical robots transforming healthcare, hydraulics play a vital role in our modern world.