- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

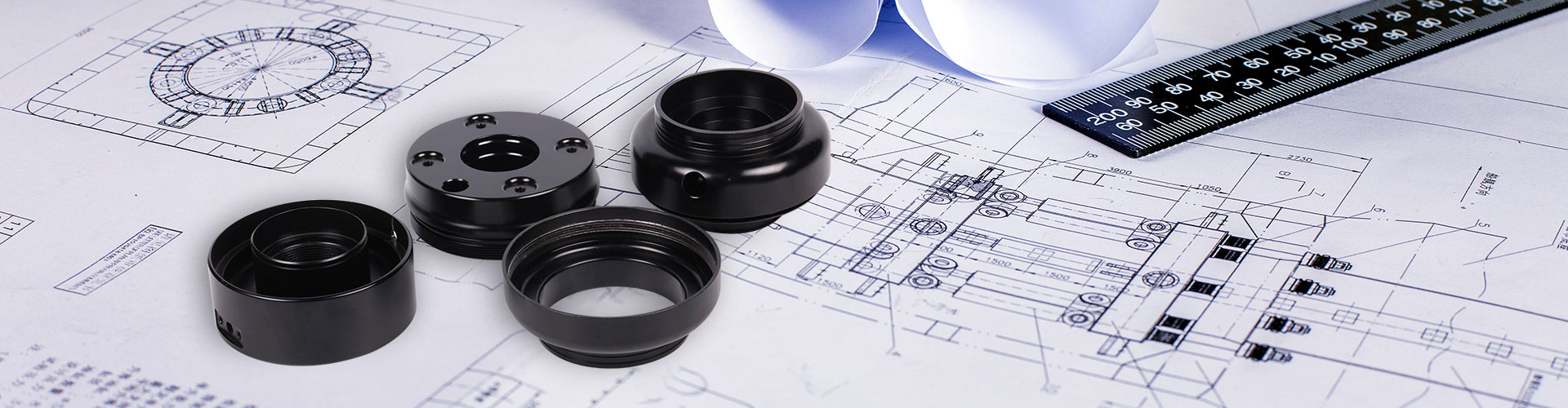

Benefits and Applications of Aluminum Die Casting

2024-05-22

The Aluminum Die Casting process starts with the creation of a die, typically made from hardened steel, which defines the shape of the final component. Molten aluminum is then forced into the die cavity at high pressures, filling the mold and forming the part. Once the aluminum cools and solidifies, the die opens, and the cast part is ejected. This process can be repeated many times, making it highly suitable for mass production.

Key Benefits of Aluminum Die Casting

1. Precision and Complexity:

One of the primary advantages of Aluminum Die Casting is its ability to produce parts with complex geometries and tight tolerances. The high-pressure injection allows for intricate details and consistent precision, making it ideal for components that require exact specifications.

2. Strength and Durability:

Aluminum alloys used in die casting offer a good balance of strength and lightweight properties. Parts produced through Aluminum Die Casting are robust and durable, capable of withstanding significant stress and wear, which is crucial for automotive and aerospace applications.

3. Cost-Effectiveness:

The Aluminum Die Casting process is highly efficient, especially for high-volume production runs. The rapid cycle times and ability to produce large quantities of parts with minimal waste reduce manufacturing costs. Additionally, the reusability of the die further lowers the overall production expenses.

4. Surface Finish and Aesthetics:

Parts produced by Aluminum Die Casting often have a superior surface finish, which can be easily polished, painted, or coated. This quality makes die-cast aluminum components attractive for consumer goods and electronics, where both functionality and aesthetics are important.

Applications of Aluminum Die Casting

The versatility of Aluminum Die Casting makes it suitable for a wide range of applications across various industries:

1. Automotive Industry:

Aluminum Die Casting is extensively used in the automotive sector for manufacturing engine components, transmission housings, and other critical parts. The lightweight nature of aluminum contributes to better fuel efficiency and performance.

2. Aerospace Industry:

In aerospace, Aluminum Die Casting is utilized to produce components that require high strength-to-weight ratios. This includes parts for aircraft engines, structural components, and various aerospace instruments.

3. Electronics and Telecommunications:

The excellent thermal conductivity of aluminum makes Aluminum Die Casting ideal for producing heat sinks, housings, and enclosures for electronic devices. It ensures effective heat dissipation, enhancing the performance and longevity of electronic components.

4. Consumer Goods:

Aluminum Die Casting is also prevalent in the production of consumer goods, such as cookware, power tools, and sports equipment. The process allows for the creation of durable, lightweight, and aesthetically pleasing products.

Challenges and Considerations

While Aluminum Die Casting offers numerous benefits, there are also challenges to consider. The initial cost of die creation can be high, making it more suitable for large production runs. Additionally, the process requires precise control of temperature and pressure to ensure the quality of the cast parts. Advances in technology and manufacturing techniques continue to address these challenges, making Aluminum Die Casting an increasingly efficient and reliable production method.

Aluminum Die Casting is a critical manufacturing process that combines precision, strength, and efficiency to produce high-quality metal parts for a variety of industries. Its ability to create complex shapes with excellent surface finishes makes it indispensable in automotive, aerospace, electronics, and consumer goods applications. Understanding the process and benefits of Aluminum Die Casting helps in appreciating its role in modern manufacturing and its contribution to producing durable and efficient products.