- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

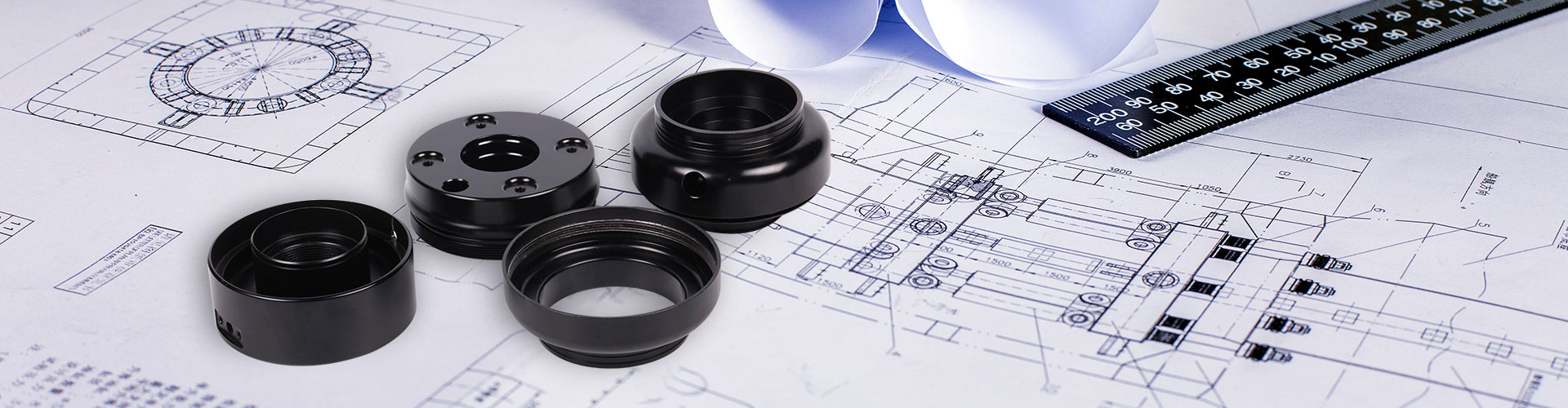

What are CNC Machining Parts?

2024-07-01

CNC machining parts refer to components and elements that are produced through the use of Computer Numerical Control (CNC) machining techniques. CNC machining is a subtractive manufacturing process that employs computer-controlled cutting tools to remove material from a workpiece, leaving behind the desired shape and dimensions.

CNC machining parts play a crucial role in various industries, including automotive, aerospace, medical, and electronics. These precision-engineered parts are crucial for the functionality and performance of complex machinery and equipment.

Here are some of the key components and features of CNC machining parts:

1. Material Selection

CNC machining parts can be made from a wide range of materials, including metals like aluminum, steel, stainless steel, titanium, and alloys. Non-metallic materials like plastics and composites are also commonly used. The choice of material depends on the specific application and requirements of the part.

2. Design and Programming

CNC machining parts are designed using CAD (Computer-Aided Design) software. The design is then converted into a CNC program, which instructs the machine on how to cut the material. The programming process involves selecting the appropriate tools, cutting speeds, and feed rates to achieve the desired results.

3. CNC Machine

The CNC machine is the heart of the CNC machining process. It consists of various components, including the input device, machine control unit (MCU), machine tools, driving system, feedback system, display unit, bed, and headstock. The input device allows CNC programs to be loaded into the machine, while the MCU interprets and executes the program instructions. The machine tools, such as drills, mills, and lathes, are used to remove material from the workpiece.

4. Precision and Accuracy

CNC machining offers high levels of precision and accuracy. The machines can achieve tolerances within microns, ensuring that parts fit together precisely and function as intended. This precision is essential for many applications, particularly in the aerospace and medical industries.

5. Customization

CNC machining allows for a high degree of customization. Parts can be designed and manufactured to meet specific requirements, including unique shapes, sizes, and features. This flexibility enables manufacturers to produce a wide range of parts for different applications and industries.

6. Cost-Effectiveness

While CNC machining may involve higher upfront costs compared to other manufacturing processes, it can be cost-effective for high-volume production runs. The machines can operate continuously, producing parts at a rapid rate with minimal human intervention. This reduces labor costs and increases overall efficiency.

In summary, CNC machining parts are precision-engineered components that are produced using computer-controlled cutting tools. They play a crucial role in various industries and offer a high degree of customization, precision, and accuracy. With the continued development of CNC technology, CNC machining parts are becoming increasingly important for modern manufacturing applications.