- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

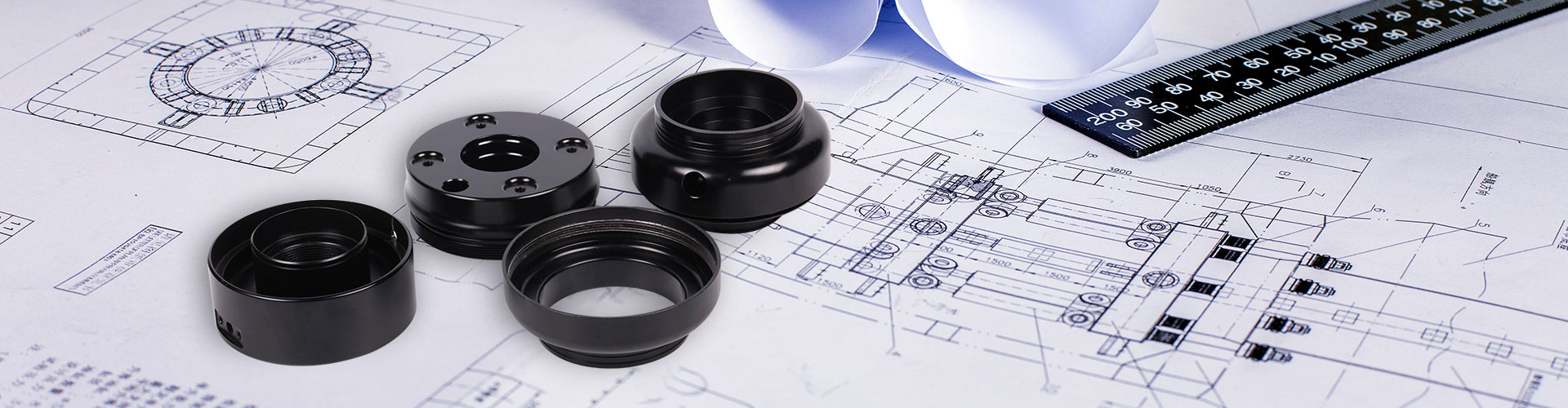

How to maintain CNC machining?

2022-06-24

CNC machining are characterized by high accuracy, high efficiency and high adaptability due to their high degree of automation. At present, it has become the main production equipment of many factories. However, the operation efficiency, equipment failure rate and service life of CNC machining largely depends on the correct use and maintenance of machine tools.

3, Do a good job of the workshop's total power, gas, liquid supply: the CNC machining Y axis run to the middle, Z axis back to zero, turn off the machine tool's total electrical switch and transformer into the line switch, gas source, etc..

4,waterproof and moistureproof: electrical box close, do a good job of waterproof and moistureproof protection.

5, machine tool anti-rat treatment: do a good job of anti-rat treatment, to prevent mice bite off the wire, causing machine failure.

1. Machine cleaning: clean up impurities after completion of work, keep the workpiece and fixture clean, and clean up impurities in the external chip discharging machine; Wipe the external sheet metal; Clean air conditioning of electric control box, filter net of oil cooler, etc.

3, Do a good job of the workshop's total power, gas, liquid supply: the CNC machining Y axis run to the middle, Z axis back to zero, turn off the machine tool's total electrical switch and transformer into the line switch, gas source, etc..

4,waterproof and moistureproof: electrical box close, do a good job of waterproof and moistureproof protection.

5, machine tool anti-rat treatment: do a good job of anti-rat treatment, to prevent mice bite off the wire, causing machine failure.