- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

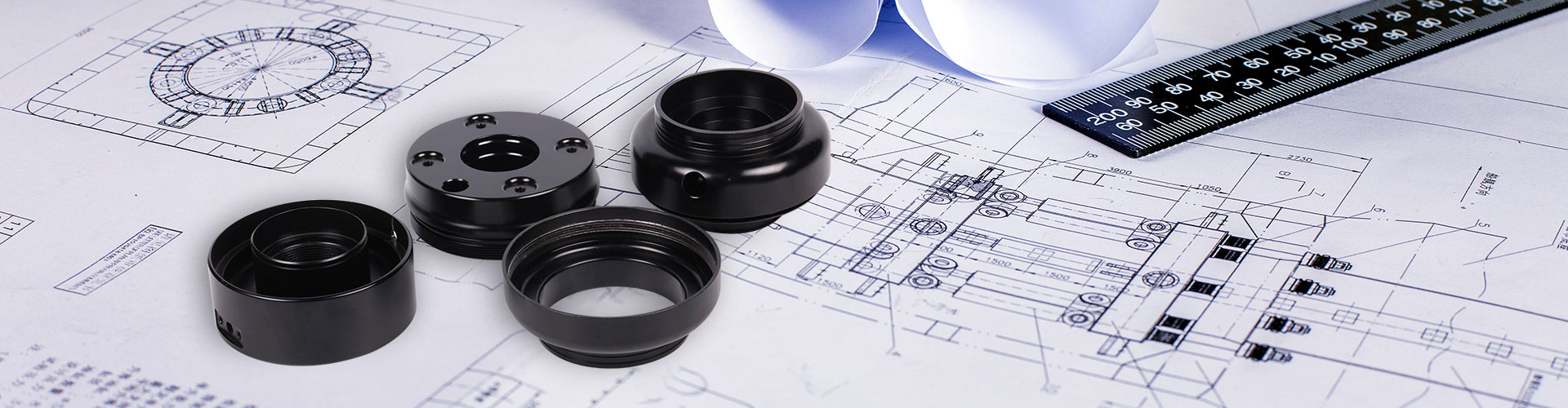

What principles should be followed when disassembling the mechanical parts of CNC machining?

2022-06-24

When mechanical failure occurs in CNC machining, disassembly is generally used to determine which parts have problems. So what principles should be followed when dismantling the mechanical parts of CNC machining?

Before disassembly, it is necessary to cut off and remove the power supply and workshop power associated parts of the CNC machining. After the power is cut off, the disassembly procedure of CNC machining should adhere to the principle of the opposite of the assembly procedure. The external accessories should be removed first, then the whole machine into component assembly, and then all into parts.When disassembling CNC lathes, we should usually adhere to the principle of how much power assembly is basically how much power disassembly. If abnormal conditions occur, the cause should be found to prevent the parts from being damaged in the process of disassembly.For the disassembly of large nc lathe parts to adhere to the principle of caution and safety. In disassembly, carefully check whether the locking screws and pressure plates are disassembled. When hanging, it is necessary to estimate the position of the center of gravity of parts, and choose the hanging rope and stress point with appropriate diameter.We should adhere to the principle of disassembling CNC machining for assembly. If the technical information of the disassembled machine equipment is not complete, the disassembly process must be recorded in order to reassemble according to the principle of disassembly before assembly during installation.

Before disassembly, it is necessary to cut off and remove the power supply and workshop power associated parts of the CNC machining. After the power is cut off, the disassembly procedure of CNC machining should adhere to the principle of the opposite of the assembly procedure. The external accessories should be removed first, then the whole machine into component assembly, and then all into parts.When disassembling CNC lathes, we should usually adhere to the principle of how much power assembly is basically how much power disassembly. If abnormal conditions occur, the cause should be found to prevent the parts from being damaged in the process of disassembly.For the disassembly of large nc lathe parts to adhere to the principle of caution and safety. In disassembly, carefully check whether the locking screws and pressure plates are disassembled. When hanging, it is necessary to estimate the position of the center of gravity of parts, and choose the hanging rope and stress point with appropriate diameter.We should adhere to the principle of disassembling CNC machining for assembly. If the technical information of the disassembled machine equipment is not complete, the disassembly process must be recorded in order to reassemble according to the principle of disassembly before assembly during installation.