- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

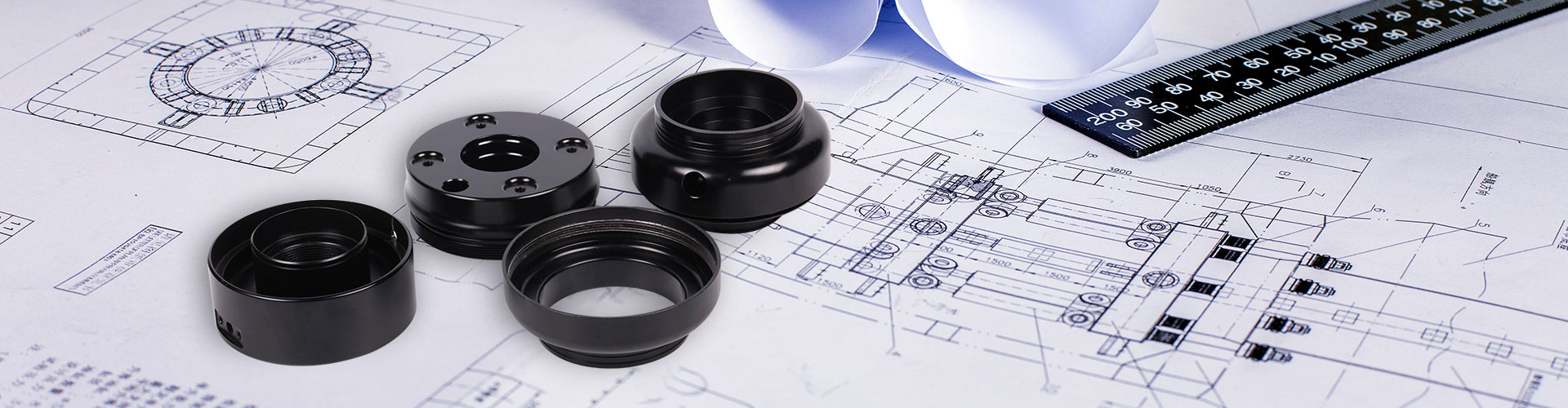

Steps to Programming CNC Machines

2022-10-14

Steps to Programming CNC Machines

The basic process of programming a CNC machine is simple. Learning and understanding the code to develop programs is the most difficult part. The steps to programming CNC machines are briefly explained below.

Step 1: A two- or three-dimensional computer-aided drawing is conceived. This drawing will be of the desired end product.

Step 2: The computer-aided drawing is translated into computer code. The translation process is done so that the CNC system can read and execute the desired functions.

Step 3: The machine operator will give the new code a trial run. This will ensure there are no mistakes present in the coding.

Step 4: If the machine programming works without error, the process is done. If there are any mistakes present in the G-Code, the operator will work to fix them. Once they are fixed, they will re-test the machine.

Once the CNC system is activated, the desired cuts will be programmed into the software. It will tell the corresponding tools and machinery what to do.

As mentioned above, this process makes CNC machines like robots. The machines will be carried out in three-dimension as specified.

Understanding Errors in CNC Machining

Although CNC machining is amazing, it isn’t perfect. One of the biggest issues is the computer assumption of perfection.

The code generator located inside the numerical system often assumes that mechanisms are flawless. It doesn’t properly register the possibility of errors.

Although the possibility of errors is always present, certain situations make it more likely. Error mostly increases when a machine is coded to cut in more than one direction at a single time.

CNC Machine Applications

They developed CNC machines out of the technology used for numerical control machines. The earliest use of the numerical control technology dates back to the 1940s.

In the 1940s, motors were used to control the movement of tools. This technology birthed mechanisms that could be controlled by analog computers.

The modern age gave birth to digital computer technology. This was applied to the pre-existing NCM technologies to create CNC machining.

The increased abilities of CNC machines have made the work of many industries simpler. Due to greater possibilities, CNC machining is now used across the manufacturing industry.

CNC machines have been designed to work with a wide range of materials. This includes metal, glass, plastic, wood, foam, and composites. We have applied them to manufacture everything from clothing to aerospace parts.

Types of CNC Machines

There are several unique types of CNC machines. The most basic functioning is the same in all these machines. Its what makes them computer numerical control systems.

The way each machine functions past that is different. How a CNC machine works will be based on what the machine is expected to do. Below are examples of some of the most common CNC machines.

CNC Mills

These can be run by programs made prompts that use both numbers and letters. The programming guides the different pieces of the machine across varying distances.

The most basic mills operate on a three-axis system. Newer models are more complex. They can operate up to a six-axis system.

Lathes

A lath cuts pieces in a circular direction. This process is done with indexed tools. They carry all cuts out with incredible precision and high velocity.

Lathe CNC machines are used to produce designs too complex for manually-ran machines. Although they create complex designs, lathes are typically not complex machines themselves. A two-axis system is most common.

Plasma Cutters

We use plasma cutting CNC machines with metal materials most often. A lot of speed and heat are necessary when making precision cuts in metal. To help achieve this, compressed-air gas is combined with electrical arches.

Wire Electric Discharge Machines

Also known as wire EDMs. These machines use electrical sparks to mold pieces into specific shapes.

Spark erosion is used to remove portions from naturally electronically conductive materials.

Sinker Electric Discharge Machines

Also known as sinker EDMs. These operate like wire EDMs. The difference is in the way electricity is conducted to remove pieces.

With a sinker EDM, work materials are soaked in a dielectric fluid to conduct electricity. This is how pieces are molded into specific shapes.

Water Jet Cutters

These machines are used to cut hard materials with high pressured water. We often use water jet cutter CNC machines with granite and metal.

We sometimes mix sand or another abrasive material into the water. This allows for more cutting and shaping power without adding heat.

CNC Drilling Machines

These use multi-point drill bits to create circular holes in the workpiece. We usually feed the drill bits perpendicular to the workpiece’s surface to create vertical holes. We can also program the process to create angular holes.