- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

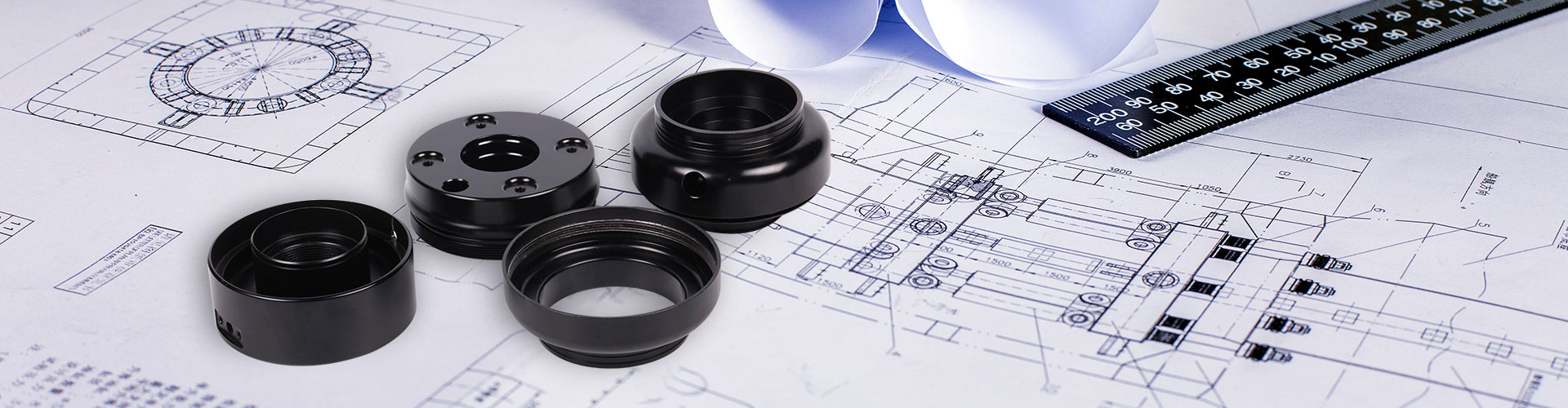

What is the high pressure aluminum die casting process?

2022-05-19

High pressure aluminum die casting is a manufacturing process in which molten metal (aluminum) is injected under pressure with a die casting machine into a steel mold or die to form a product.

Due to the dimensional accuracy and smooth surface, most high pressure die castings do not require machining to remove burrs around the edges and possibly drilled and tapped holes. Compared to other casting processes, high pressure casting is fast and inexpensive to produce.

At present, 80%-90% of the world's high pressure die casting alloys use aluminum. In many cases, aluminum high pressure die castings can replace steel, increasing strength and reducing part weight.

Due to the dimensional accuracy and smooth surface, most high pressure die castings do not require machining to remove burrs around the edges and possibly drilled and tapped holes. Compared to other casting processes, high pressure casting is fast and inexpensive to produce.

At present, 80%-90% of the world's high pressure die casting alloys use aluminum. In many cases, aluminum high pressure die castings can replace steel, increasing strength and reducing part weight.

Previous:No News