- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

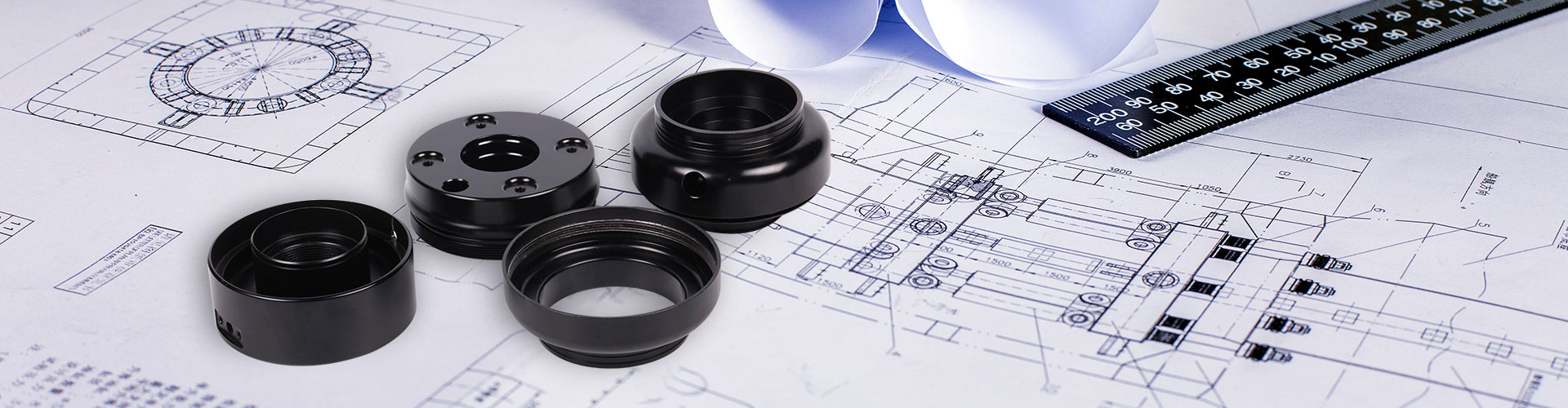

How to maintain the CNC turning and milling compound machine tool?

2022-05-18

The quality of CNC turning and milling compound machine tool maintenance can directly affect the processing quality and work efficiency of CNC Milling Car Machined Parts. The standard of such lathes should prevent direct sunlight and other thermal radiation, and prevent places that are too humid, too dusty or corrosive gas. It is not suitable for long-term shutdown. The best choice is to turn on the power once or twice a day, and run empty for about an hour each time, so as to use the heat generated by the lathe to reduce the relative humidity inside the machine, so that the electronic components will not be affected by moisture. At the same time, it can also find out whether there is a battery alarm in time to prevent the loss of system software and data. The spot inspection of CNC lathe with inclined bed is the basis for carrying out condition monitoring and fault diagnosis, which basically involves the following information:

1. Fixed point. The first step is to confirm how many maintenance points a CNC lathe with inclined bed has, scientifically analyze the machine and equipment, and select the location where problems are likely to occur. Just "watch" these maintenance points, and problems will be discovered in time.

2. Calibration. For each maintenance point of the boat, it is necessary to formulate standards one by one, such as clearance, temperature, pressure, flow, tightness, etc., all need to have accurate quantity standards, as long as they do not exceed the standards, it will not be a problem.

3. Periodically. When to check once, the inspection cycle time should be given, and it should be confirmed according to the actual situation.

4. Set items. What items are checked at each maintenance point also need to be clearly stipulated.

5. Set people. Who will carry out the inspection, whether it is the operator, maintenance personnel or technical personnel, should be implemented according to the inspection location and technical accuracy standards.

1. Fixed point. The first step is to confirm how many maintenance points a CNC lathe with inclined bed has, scientifically analyze the machine and equipment, and select the location where problems are likely to occur. Just "watch" these maintenance points, and problems will be discovered in time.

2. Calibration. For each maintenance point of the boat, it is necessary to formulate standards one by one, such as clearance, temperature, pressure, flow, tightness, etc., all need to have accurate quantity standards, as long as they do not exceed the standards, it will not be a problem.

3. Periodically. When to check once, the inspection cycle time should be given, and it should be confirmed according to the actual situation.

4. Set items. What items are checked at each maintenance point also need to be clearly stipulated.

5. Set people. Who will carry out the inspection, whether it is the operator, maintenance personnel or technical personnel, should be implemented according to the inspection location and technical accuracy standards.