- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

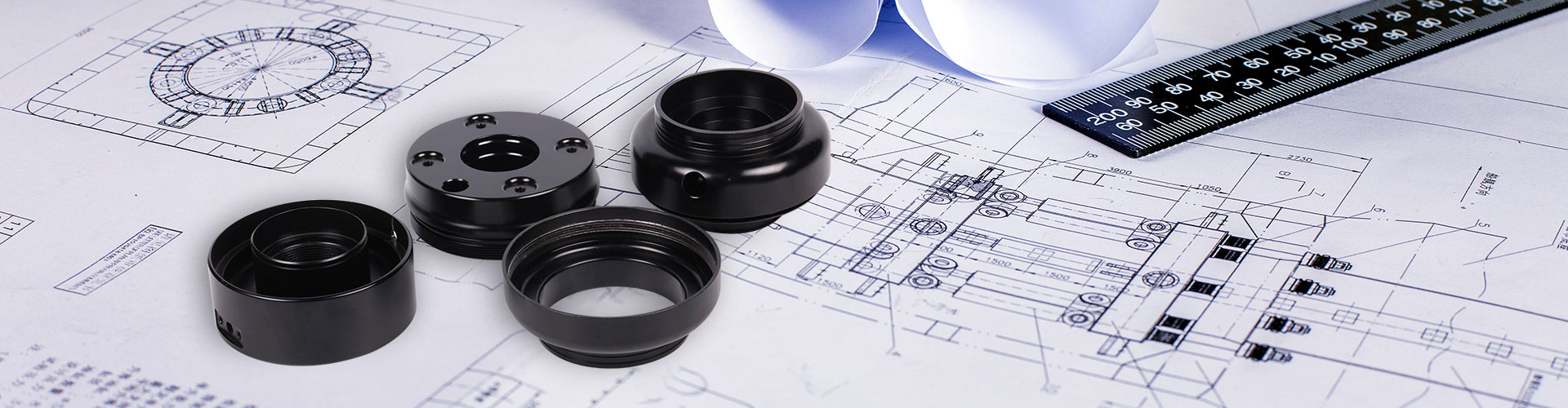

sand casting process of RUICAN

2023-11-15

The process of sand casting involves the following steps:Pattern Creation: A pattern is created using wood or metal of the required shape.Mold Preparation: A two-piece mold is created using sand. The pattern is placed in one half of the mold which is then filled with sand over the pattern. The other half of the mold is placed over the first half and secured together.Pouring the Liquid Metal: The molten metal is poured into the mold through a sprue which is a channel in the mold. The metal fills the cavity left by the pattern.Cooling: The metal cools and solidifies inside the mold.Shakeout: The solidified casting is removed from the mold by breaking open the mold. The casting is then cleaned to remove the sand and any other debris.Finishing: Any extraneous material such as gates or risers are removed from the casting. The casting may also be machined or polished, depending on the final application.