- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

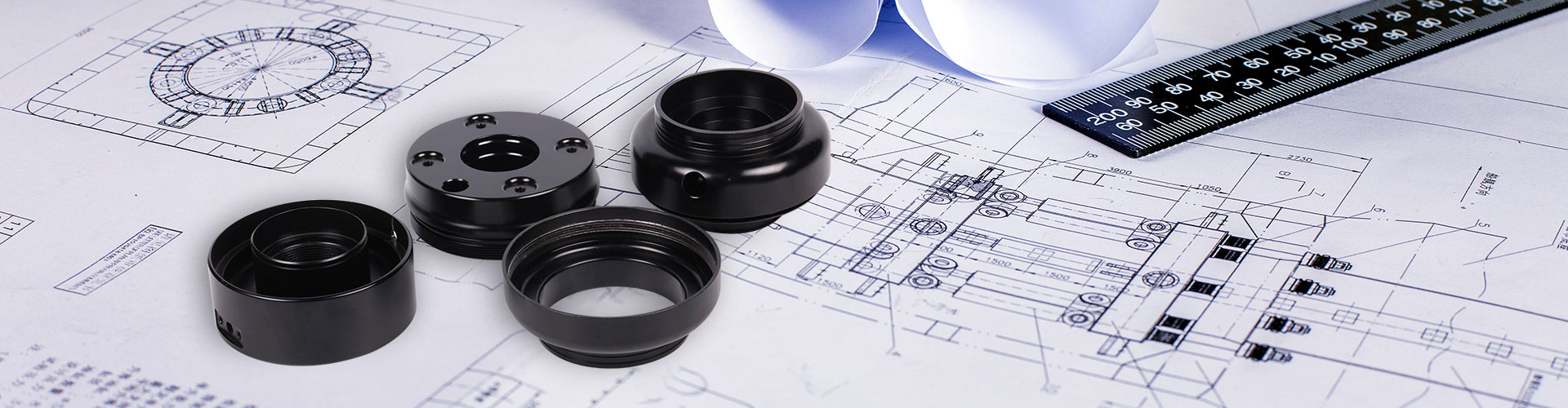

Precautions for CNC precision parts processing

2023-05-04

1. Precautions for CNC precision parts processing

(1) When the workpiece is too high, different lengths of knives should be used to cut the thickness layer by layer. After using a large knife to cut the thickness, a small knife should be used to remove the remaining material.

(2) Use flat bottomed knives to process flat surfaces, and use fewer ball knives to reduce processing time; If there is a slope and it is an integer, use a slope knife for processing.

(3) Reasonably set tolerances to balance machining accuracy with computer calculation time, do more processes, and reduce empty tool time.

(4) High hardness of raw materials, select reverse milling; The hardness of the raw material is low, so it is necessary to choose a smooth milling method. Rough machining reverse milling, precision machining forward milling.

(5) The tool data has good durability and low hardness, and is used for rough machining, while the tool data has poor durability and high hardness, and is used for precision machining.

2. CNC machining process

(1) Part clamping method and fixture selection

The clamping method for the processed parts on CNC machine tools should also be reasonably selected for positioning reference and clamping plan. When selecting precision reference, it is generally necessary to follow the two criteria of "consistent reference" and "overlapping reference". In addition to these two criteria, we also need to consider:

a. Try to complete all surface processing in one positioning clamping, therefore, choose a positioning method that is convenient for processing all surfaces.

b. When the workpiece is clamped at once, it should be able to complete all external processing of the workpiece.

c. When determining the placement position of the workpiece on the workbench, consideration should be given to the impact of processing at each workstation, tool length, and tool stiffness on processing quality.

d. The fixtures used in control machining should be selected as much as possible, which are assembled from universal components and can be adjusted to shorten the production preparation cycle.

(2) Organization of processing sequence

When organizing the processing sequence, the basic principles must be adhered to, including "first surface, then hole", "first rough, then fine", etc. In addition to these basic principles, we should also follow the following principles:

a. Process according to the tool assembly process to prevent repeated use of the same tool and reduce the number and timing of tool changes.

b. For hole systems with high coaxiality requirements, the machining of the hole system should be completed after a single positioning, and then the hole system in other coordinate positions should be processed. This can eliminate errors that occur during repeated positioning and improve the coaxiality of the hole system.

(1) When the workpiece is too high, different lengths of knives should be used to cut the thickness layer by layer. After using a large knife to cut the thickness, a small knife should be used to remove the remaining material.

(2) Use flat bottomed knives to process flat surfaces, and use fewer ball knives to reduce processing time; If there is a slope and it is an integer, use a slope knife for processing.

(3) Reasonably set tolerances to balance machining accuracy with computer calculation time, do more processes, and reduce empty tool time.

(4) High hardness of raw materials, select reverse milling; The hardness of the raw material is low, so it is necessary to choose a smooth milling method. Rough machining reverse milling, precision machining forward milling.

(5) The tool data has good durability and low hardness, and is used for rough machining, while the tool data has poor durability and high hardness, and is used for precision machining.

2. CNC machining process

(1) Part clamping method and fixture selection

The clamping method for the processed parts on CNC machine tools should also be reasonably selected for positioning reference and clamping plan. When selecting precision reference, it is generally necessary to follow the two criteria of "consistent reference" and "overlapping reference". In addition to these two criteria, we also need to consider:

a. Try to complete all surface processing in one positioning clamping, therefore, choose a positioning method that is convenient for processing all surfaces.

b. When the workpiece is clamped at once, it should be able to complete all external processing of the workpiece.

c. When determining the placement position of the workpiece on the workbench, consideration should be given to the impact of processing at each workstation, tool length, and tool stiffness on processing quality.

d. The fixtures used in control machining should be selected as much as possible, which are assembled from universal components and can be adjusted to shorten the production preparation cycle.

(2) Organization of processing sequence

When organizing the processing sequence, the basic principles must be adhered to, including "first surface, then hole", "first rough, then fine", etc. In addition to these basic principles, we should also follow the following principles:

a. Process according to the tool assembly process to prevent repeated use of the same tool and reduce the number and timing of tool changes.

b. For hole systems with high coaxiality requirements, the machining of the hole system should be completed after a single positioning, and then the hole system in other coordinate positions should be processed. This can eliminate errors that occur during repeated positioning and improve the coaxiality of the hole system.

c. Select the determined cutting point and tool change point, and once determined, it is not advisable to replace them.