- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

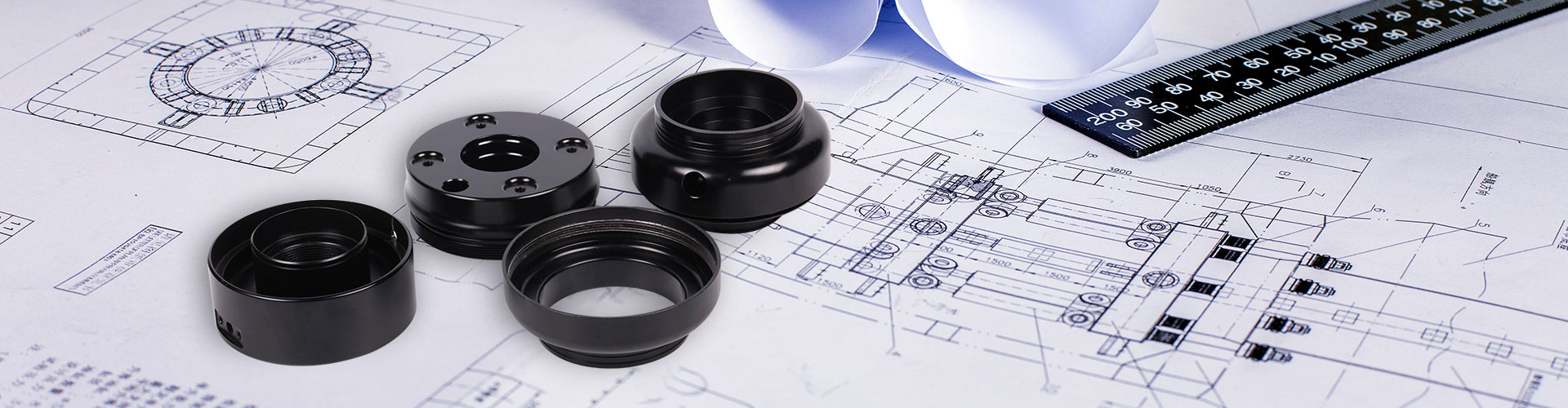

What are the advantages of Investment Casting?

2022-10-17

Investment casting, also known as lost wax casting, includes wax pressing, wax repairing, tree forming, pulp dipping, wax melting, casting metal liquid and post-treatment and other processes. Lost wax casting is to make a wax mold of the parts to be cast with wax, and then the wax mold is coated with mud, which is the mud mold. After the clay mold is dried, melt the inner wax mold in hot water. After melting the wax mold, the clay mold is taken out and then roasted into a pottery mold. Once roasted. In general, a casting opening is left for making a mud mold, through which molten metal is poured. After cooling, the required parts are made.

The biggest advantage of investment casting is that because of the high dimensional accuracy and surface finish of investment casting, it can reduce the mechanical processing work. Only a little processing allowance can be left for the parts with high requirements. Even some castings can only be left for polishing and polishing, so they can be used without mechanical processing. It can be seen that the use of investment casting method can greatly save machine tools and equipment and processing hours, and greatly save metal raw materials.

The biggest advantage of investment casting is that because of the high dimensional accuracy and surface finish of investment casting, it can reduce the mechanical processing work. Only a little processing allowance can be left for the parts with high requirements. Even some castings can only be left for polishing and polishing, so they can be used without mechanical processing. It can be seen that the use of investment casting method can greatly save machine tools and equipment and processing hours, and greatly save metal raw materials.