- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

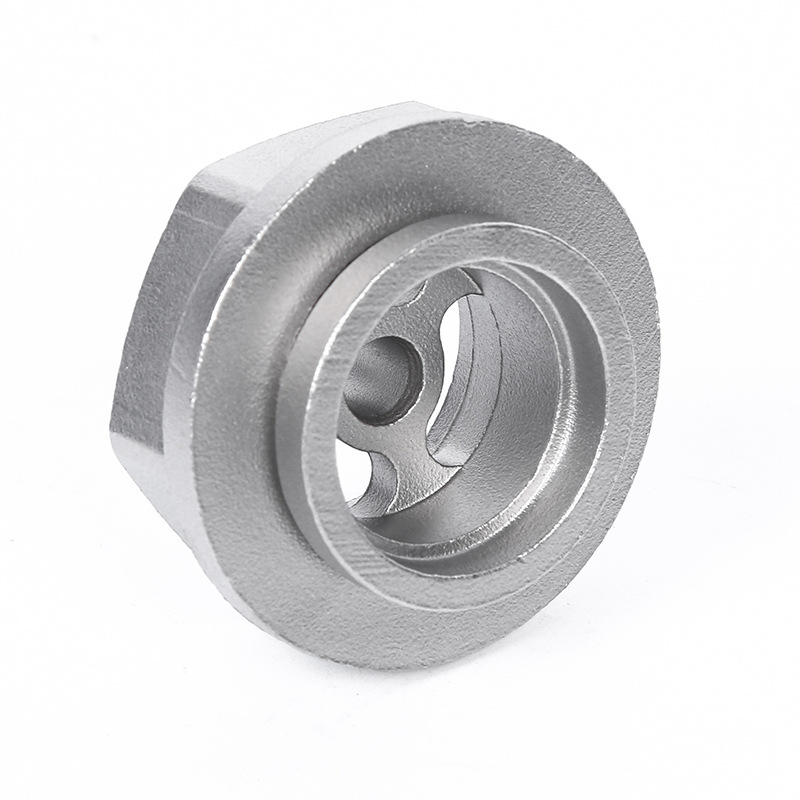

Lost Wax Investment Casting Stainless Steel Parts

Our company specializes in thigh-quality Lost Wax Investment Casting Stainless Steel Parts. We use advanced technology and techniques to manufacture parts that meet or exceed the needs of our customers. Our wax investment casting process involves the production of a wax pattern, which is then covered with a ceramic shell that is fired at high temperatures to create a mold. Molten metal is then poured into the mold, which is subsequently removed, to reveal a part that has been intricately engraved with an incredible level of detail and precision.

Send Inquiry

We are OEM & ODM, precision casting lost wax process is a specialized method we utilize to create intricately shaped parts that require high levels of accuracy and precision. We use advanced software systems and high-precision machines to create parts that are an exact match of our customer's requirements.

Our inventory of Lost Wax Investment Casting Stainless Steel Parts products spans a broad range of industries, from aerospace to automotive and dental product manufacturing. We offer a range of casting alloys, including stainless steel, carbon steel, alloy steel, and others, allowing us to produce parts that are uniquely suited to our customers' needs.

Investment casting by lost wax process is a highly effective method of producing precision parts with exceptional accuracy and durability. Contact us today to learn more about our products and services, and how we can help turn your idea into a reality.